Steam boiler systems are irreplaceable in the chemical process industries. Among various manufacturing and process industries, chemical industries are considered hazardous places to work due to their high probability of volatile components, the risk of explosions, and fires. Therefore, boiler safety is the highest priority in the chemical industry. Comprehensive examination and maintenance of the steam boiler ensure the safety of the process plant. Read the article to understand the importance of regular boiler assessment and maintenance in the chemical industries.

Understanding the role of steam boilers in the chemical industry:

Steam is extensively useful in chemical processing for various operations ranging from heating fluids to driving equipment. The steam boiler system that generates the steam from water comes in many different varieties and sizes. Let us look at the types and designs of steam boilers for chemical process plants, as well as issues related to their safety, reliability, and efficient operation.

Steam boilers depend on the combination of radiant and convective heat transfer, consisting of a furnace section and steam-containing parts. A lower mean temperature difference between the hot gas and the steam generally requires an increase in the surface of tubing and boiler weight. High-temperature boilers need special alloys like nickel-based for their hot section.

Designs of Boilers in the Chemical Industry:

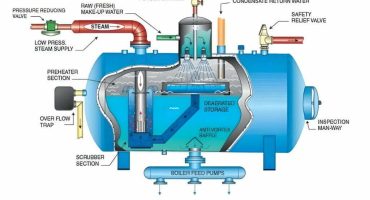

Among various types of designs in steam boilers for the chemical industry, a commonly used configuration uses a steam drum. It involves the water entering the boiler through the economizer and passing to the steam drum. The water passes through the down comers to the lower inlet water-wall headers, rises through the water walls, and changes to steam due to the heat generated. The steam enters the steam drum and moves through multiple steam and water separators and dryers in the steam drum. It eliminates the water droplets from the steam and the cycle. Forcing the water into the steam boiler requires a special set of feedwater pumps.

Another variant is a basic design termed once-through boilers. The system does not include a steam drum. The water travels through the economizer, the furnace wall tubes, and the super heater section in a continuous pass without recirculation. A set of feedwater pumps supplies the required force for the flow through the steam boiler.

Safety and Reliability of Operations in the Chemical Industry:

Proper control and safety devices are very essential to ensure the safety and reliability of the process operations. Safety or relief valves are the primary safety feature on a steam boiler, preventing dangerous over-pressurization. Safety valves are required in case there are any failures of pressure controls or other devices controlling the firing rate.

The majority of boiler issues, failures, and accidents are preventable in the chemical industries. One of the most effective ways to avoid such problems is condition monitoring. Most boiler issues do not occur suddenly but develop gradually over a long period. The ideal way to detect important changes that may otherwise be neglected is to comprehensively record condition data and carefully evaluate those data periodically.

Importance of Steam Boiler Maintenance:

Neglecting regular steam boiler maintenance can lead to serious issues. It is especially true in chemical processing plants, which pose a greater risk to the operating personnel due to the volatile substances they work with.

Ensuring regular inspection and maintenance plans ensure that the boiler is safe to operate. By following a schedule, any potential problems can be identified before it becomes a major issue. Safety should be the utmost concern, particularly while heating chemical reactors, which may result in serious harm to staff and damage to property.

The steam boiler maintenance is also necessary for efficiency. Neglecting steam boiler maintenance leads to increased expense due to reduced efficiency. If an issue is neglected during maintenance, it could lead to larger issues that impact the plant’s efficiency. A sudden downtime after a boiler failure can be extremely costly to the business.

Maintenance Checklist for Steam Boilers:

Regardless of a steam boiler type or design, it will always require regular maintenance. Below is a list of factors that should be examined during maintenance,

- Boiler Construction and Design

- Water Quality and Treatment

- Ample Space for Emissions

- Advanced Boiler Monitoring

- Regular Inspections

Conclusion:

Steam boilers have a crucial impact on the processing operations of chemical plants in terms of efficiency and productivity. Chemical industries require an ample amount of high-temperature steam for effective operations. Secondly, chemical industries tend to generate a large amount of emissions and waste heat. Therefore, it is essential to check that every requirement is met, before selecting a boiler manufacturer for a chemical plant.

Rakhoh Boilers manufactures highly efficient and reliable steam boilers preferred and trusted by various chemical process plants. Rakhoh’s Optipac and Waste Heat Recovery Boiler is an ideal choice for many chemical plants.