- Home

- About Us

- Products

- EPC projects

- Technology

- Services

- Clients

- Media

- Blog

VIEW ALL -

06 July 2024 by bullweb, in Boiler

06 July 2024 by bullweb, in BoilerKey Considerations When Choosing a Steam Boiler Manufacturer

It is an important decision to select the right steam boiler manufacturer holdin...READ MORE + 19 July 2023 by bullweb, in Boiler

19 July 2023 by bullweb, in BoilerA Guide to Boiler Maintenance in Chemical Processing Plant

Steam boiler systems are irreplaceable in the chemical process industries. Among...READ MORE + 19 October 2022 by bullweb, in Steam Boiler,Steam Jackets

19 October 2022 by bullweb, in Steam Boiler,Steam JacketsSteam Jackets in Boilers | Definition, Types, and Applications

Steam is integral to meet various process operational requirements in manufactur...READ MORE +

- Careers

BOILER ACCESSORIES, THERMIC FLUID HEATERS & SPECIALTY FABRICATION.

+9120 - 66308333

Email: enquiry@rakhoh.com

RAKHOH BOILERS

S-11, T Block, M.I.D.C.,Bhosari, PUNE - 411 026. Maharashtra, India

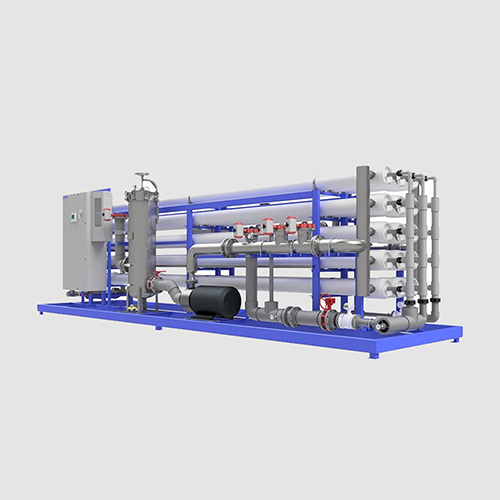

Water Filtration Plant EPC

Water Filtration Plant EPC

At Rakhoh, we offer services for Full fledged turnkey solutions comprising Design, Engineering, Procurement, Manufacturing, Inspection, Supply, Construction, Installation, Commissioning, and Operation on a Turnkey basis along with a process guarantees. Our organization is focused on providing eco-friendly, low-cost innovative treatment solutions for industrial water filtration. Rakhoh, with its strength as an industry-leading global EPC firm with specialized water and wastewater engineering capabilities offers clients an integrated solution. It leads to a comprehensive approach that ensures value to clients particularly related to water management on their site. With 120 installations, Rakhoh has been creating a successful track record.

A water softener solves one of the most common and dangerous water issues: hard water. Ion exchange is the method by which water softeners remove calcium and magnesium from the water. We offer commercial water softening systems for converting hard water to soft water.

Water Softener Types:

- Ion Exchange Water Softener

- Water Softener Systems That Do Not Use Salt

- Water Softener System with Two Tanks

- Descaler or Magnetic Water Softener

The most common water softening procedures are the elimination of Calcium ions+ (Ca2+) and Magnesium ions+ (Mg+) from a system or the sequestration of the ions, i.e., attaching them to a molecule that prevents them from forming scale or interfering with soaps.

The Features of water softener are:

- Hardness removal

- Low civil-construction cost and low weight

- Easy Controls

- Quick Recharge

- Durable

- Low maintenance

- To achieve water potability parameters

The Applications of water softener are:

- Human and animal consumption

- Agricultural purposes

- Steam generation plant

- Pre-treatment in WTP, DM & RO projects

- Textile, sugar, dairy industries

- Automobile industries

Reverse osmosis works by increasing the pressure on the saline side of the RO and forcing the water past the moderately RO membrane, releasing practically all of the dissolved salts in the reject stream (about 90 percent to 99 percent). Reverse osmosis is a tried-and-true method of treating water that is suited for a wide variety of applications that require deionized or demineralized water.

We provide commercial reverse osmosis (RO) water treatment systems that transform high TDS water into low TDS water.

The Features of the Reverse Osmosis System are:

- Removal of dissolved salts.

- Energy-saving separation technique.

- Utilizable as a concentration and recovery method.

- Compact equipment.

- Simple operation and control.

- Useful for superior quality water usage.

The Applications of the Reverse Osmosis System are:

- Drinking water supply schemes for Local bodies.

- Food processing & milk industries.

- Sugar Factories.

- Other industries where water is used in mfg process.

- Domestic RO for household use.

Demineralized water, also referred to as Deionized water, is water that had its mineral particles removed. Mineral ions like ionic species of sodium, calcium, iron, and copper, as well as anions such as chlorine, sulfate, nitrate, etc., are common ions found in water.

Demineralization seems to be the process of eliminating mineral salt from seawater by ion exchange. Demineralization may be used with many of these natural water sources to treat water in better quality and at low-cost than standard distillation.

Ion exchange is a quick and reversible process in which contaminant ions in water are exchanged with ions produced by an ion-exchange resin. The contaminant ions are overtaken by the resin that must be renewed regularly to return to its original ionic state.

Two-Bed Ion Exchange:

The two-bed deionizer includes two vessels – one with a cation-exchange resin in the hydrogen (H+) form and the other consisting of an anion resin in the hydroxyl (OH-) form. As water flows through the cation column, all the cations are exchanged for hydrogen ions. For keeping water electrically balanced, one hydrogen ion is exchanged for every monovalent cation and two hydrogen ions are exchanged for every divalent cation. It similarly applies during anion-exchange. The decationised water passes through the anion column. As a result, all the negatively charged ions are exchanged for hydroxide ions and later combine with the hydrogen ions to form Water (H2O).

Mixed-Bed Ion Exchange:

The water quality provided by mixed-bed anion exchange is considerably higher than dual-bed devices. The usage of a variety of ion exchange resins is the most noteworthy feature of the units. The combination is maintained in a selective ion column. The DM water plant’s one-of-a-kind operating technique efficiently handles the issue of salt leakage.

The Features of Demineralized Water Plant:

- Variety of cost-effective standard models.

- User friendly, low maintenance, and easy to install.

- Simpler distribution and collection systems.

- Quick availability

- The multiport valves are top-mounted as well as side-mounted with the necessary high-pressure rating PVC piping.

- Each operating step is marked on the valve, thereby eliminating the chances of error in the operating sequence.

- Single valve assembly, with its simplified frontal Piping, and simpler distribution collecting systems are very easy to install.

- Less power consumption

- Economical

The Applications of DM Plants:

- Boilers feed Water,

- Textiles,

- Pharmaceuticals,

- Chemicals,

- Breweries,

- Swimming pools,

- Potable Water,

- Hospitals, Automobiles, and Battery Fertilizers.

- Ion Exchange Plants

Ultrafiltration is a critical procedure for efficiently and effectively separating microorganic particles and colloids from water. The procedure is used as a pre-treatment for ion and RO exchange. Ultrafiltration is a separating method that employs membranes with pores ranging from 0.01 to 0.001 microns in size. The process is used to remove high-molecular-weight contaminants. Physical and chemical polymeric molecules, as well as colloidal debris, can be removed.

Ultrafiltration Systems Are Divided Into Two Types:

Use: These are most commonly seen in under-the-counter drinking water dispensers.

Entry: These are commonly used to run water for purposes that do not require finely filtered water.

The Features of Ultra Filtration Water Plant:

- Suspended solids & Organic impurity removal

- Less power consumption

- Utilizable as a concentration and covary method.

- Compact equipment.

- Simple operation and control.

- Useful for superior quality water usage.

The Applications of Ultra Filtration Water Plant

- Industrial Process and Wastewater

- Oil Removal in Wastewater Treatment

- Dissolved NOM in Surface Water

- Dairy

- Biotech / Pharmaceutical

- Food & Beverage

- Gelatin concentration & purification

A filter that removes iron from water is known as an iron removal filter. These are made to remove extra iron from the feed water with the least amount of pressure decrease. It aids in the treatment of hard water by eliminating minerals and softening the water. The presence of iron in water causes issues with the design, cost, and operation of companies.

The oxidation of iron is the most common working mechanism for eliminating iron content from the water. The ferrous or dissolved (soluble) state of iron is transformed into the ferric or undissolved state in this process.

The Benefits Of Iron Removal Plants

- Sediment Removal

- Cost-Effective

- Rust and Sulphur Removal

- Regeneration

The Features Of Iron Removal Plants:

- Increased solid removal

- Ensures processing stability

- The hexagonal tube shape provides better tube drainage

- Better drainage reduces blockage cleaning

- Fewer tube blockages increase effective settlement rates

- In-tube contact flocculation

The Applications Of Iron Removal Plants:

- Hospitals & other medical institutes

- Municipality water supply

- Chemical plant

- Community purpose in rural areas

- Residence

- Hotels

- Pharmaceutical industry