Importance of Welding for Steam Boiler Manufacturing

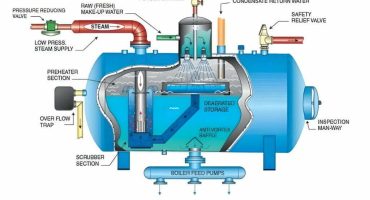

Industrial steam boilers are irreplaceable in almost every industry throughout the world. The energy holding capacity and safety in using steam is a major cause of steam boilers being an ideal choice for process operations. Therefore, industries consider every factor while selecting a steam boiler manufacturer. The quality of the steam boiler is a crucial aspect in deciding on a boiler company. The precision and utilization of high-tech machinery play a vital role in ensuring the superior quality of steam boilers. A steam boiler is manufactured of three primary components i.e. a cylinder, a base, and a cover. Rakhoh Boilers, as a leading steam boiler manufacturer, ensures that the steam boilers are fabricated with utmost safety and precision with excellent welding.

Welding in Steam Boilers:

Welding is a process involving fabrication that joins materials, usually metals or thermoplastics, through fusion, varying from lower temperature metal-joining techniques like brazing and soldering that do not melt the base metal. Combined with melting the base metal a filler material is usually added to the joint, forming a pool of molten material to cool and form a joint. It is generally stronger than the base material. Pressure may also be used jointly with heat or by itself for producing a weld.

Contrary to brazing and soldering that do not involve the melting of base metal, welding includes a high heating process that melts the base material by usually adding filler material. As a result, the high heat causes a weld pool of molten material. Pressure is also used for producing a weld along with the heat or by itself. It also utilizes a shielding gas for protecting the melted and filler metals from contamination or oxidation. A weld joint in a steam boiler is designed for withstanding the subjected forces during its lifespan. Therefore, the design of the joint is decided by the type and load magnitude on the weld.

The welding process is generally categorized as:

Gas welding: Gas welding includes oxy-acetylene gas welding and hydrogen gas welding.

Arc welding: Arc welding includes metal arc welding (SMAW ), submerged arc welding (SAW ), gas metal arc welding (MIG, MAG), electrode slag metal arc welding, tungsten inert gas welding (TIG), flux-cored arc welding(FCAW ), etc.

Resistance welding: Resistance welding includes percussion welding, seam welding, and spot welding.

Thermit welding: Thermit welding involves producing heat by exothermic chemical reactions.

Solid-state welding: Solid-state welding involves friction welding, forge welding, pressure welding, etc.

Special welding process: Special welding processes include electron beam welding, diffusion welding, plasma arc welding, underwater welding, ultrasonic welding process, etc.

Requirements of Tube Welding in Steam Boilers:

The characteristics of boiler tube welding include,

The strength and consistency of the weld are pivotal considerations in determining the ideal way to weld the pressure vessel tubes as the tubes carry high-pressure steam or liquids in a flowing pattern that can cause a loss in efficiency due to turbulence or distortion.

One of the most crucial aspects of welding boiler tubes is to determine the ideal option between orbital welding and manual welding. Factors like industrial application tube quantity and safety should be the paramount priority. Therefore, manual welding is the least likely option because of the lack of accessibility.

Additionally, the welder must decide the best technique to apply. As gas-shielded welding processes are more consistent than other techniques, MIG and TIG are the ideal alternatives. However, MIG leads to the spattering of filler that negatively impacts the weld quality and bead appearance. On the other hand, TIG uses tungsten electrodes, producing the highest purity welds. Narrow Groove TIG or Thick Wall welding processes are best suited for the thick wall boiler applications found commonly in power plants.

Tungsten Inert Gas Welding with tungsten electrodes results in the highest-quality and consistent welds. Implementing an orbital welding process reduces the lack of accessibility, making it easier for consistency throughout the welding. However, attributes like good heat control, process stability, and fixed position tube welding capability with automated controls should be considered by steam boiler manufacturers for welding machines.

Common Hazards with Welding:

Welding leads to hazardous consequences for both welders and those working in the vicinity. Therefore, it is essential to ensure precautions to prevent accidents and injuries.

Electric Shock:

As a welder touches two metal objects with a voltage difference leads to the electric shock that can cause severe injuries or death. It is further classified as,

Primary shock:

It ranges from 230 to 260 volts that occur by having direct contact with the inside of welding equipment and other grounded metals. Primary shock is extremely hazardous

Secondary shock:

It is the most common type of shock occurring while touching the electrode circuit that ranges from 20 to 100 volts

Prevention for Electric Shock:

Fire Hazards:

Welding sparks spray up to 35 feet and may cause fire hazards, severely impacting the workers with grease on their clothing.

Prevention for fire hazards:

Fumes and Gases:

Welding introduces the personnel to gaseous fumes like ozone, nitrogen, and carbon monoxide that may cause asthma, pneumonia, or cancer.

Prevention for Fumes and Gases:

Physical Hazards:

Various physical hazards are involved in welding activities like burns, cuts, crushed fingers, and eye damage.

Prevention for physical hazards:

Conclusion:

Rakhoh Boilers is a leading steam boiler manufacturer since its inception in 1983. We are a trusted name in over 26 countries for delivering efficient steam boilers, waste heat recovery systems, thermic fluid heaters, boiler accessories, and boiler services of world-class quality.

For more details, visit www.rakhoh.com

- Published in Boiler, Steam Boiler