An Introduction to Reverse Osmosis in Steam Boilers with its Advantages and Disadvantages

Steam boilers and their operation are integral in the process and manufacturing industries. Boiler water is pivotal in ensuring the proper functioning of the boiler system. Reverse osmosis in steam boilers refers to a crucial process that ensures high-quality boiler water for steam generation. Boiler water includes two important resources, steam condensate return and makeup water. Earlier, there were few alternatives to increase the boiler water quality through softening or demineralizing the makeup water or increasing the condensate return. However, with recent advancements, the efficiency of Reverse Osmosis (RO) has tremendously improved in the quality of water produced, the quantity of water, and the cost of operating the system.

What is Reverse Osmosis in Steam Boilers?

Reverse osmosis in steam boilers is a process used for the extraction of mineral content and impurities from the boiler water. Reverse osmosis in steam boilers is usually performed to purify brackish water into freshwater or to make water consumable through the removal of minerals from the water. The bottled water in markets often promotes their brand as reverse osmosis (RO) purified water.

Role of Reverse Osmosis in Steam Boilers:

Reverse osmosis in the steam boiler is essential for the purification of boiler water and the performance of steam boiler systems. Reverse osmosis in steam boiler ensures two important factors:

- Purification of the boiler water for cooking purposes:

Steam boilers utilized for food or brewing process operation require reverse osmosis to ensure the hot water is consumable and would not negatively impact the taste of the processed product.

- Safeguarding the steam boiler from mineral buildup:

As boiler water boils, it turns to steam and releases into the air as a gas. Contrary to water, the salt and other minerals in the steam fail to evaporate. As a result, these minerals consequently build up as scales inside the steam boiler system, leading to the formation of hotspots and inefficiency in performance, and in severe cases, system failures. Reverse osmosis in the steam boiler eliminates the mineral content before the boiler water is fed to the feedwater tank, thus ensuring hassle-free operation of the steam boiler.

Working of Reverse Osmosis in Steam Boilers:

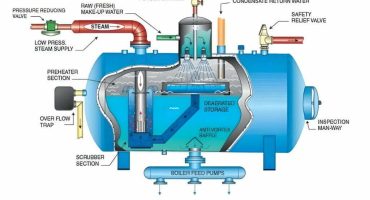

Reverse osmosis is an effective technique used for purifying boiler water. Reverse osmosis in a steam boiler operates by forcing a stream of pressurized water through a semi-penetrable membrane that eliminates bacteria, contaminants, and other small particles, thereby purifying the boiler water.

With the technical advancement in reverse osmosis, it now offers water flowing out of the membranes at almost 100% purity in some cases.

Advanced reverse osmosis in steam boilers uses a reduced pressure flow of water, resulting in low energy used in the pumps and, consequently, less cost.

Advantages of Reverse Osmosis in Steam Boiler:

- Considerable increase in the steam boiler cycles of concentration and reduced heat loss

- Reduced use of makeup water

- Over 98% removal of dissolved solids in the boiler water, including salts causing scale formation that reduces heat transfer

- Increased efficiency of the steam boiler with minimal boiler deposits

- Reduction of alkalinity in boiler water through the direct result of less neutralizing amine use

- Reduction in fuel cost and makeup water for heating as well as clean heat transfer surfaces

Disadvantages of Reverse Osmosis in Steam Boilers:

- Initial investment cost of the equipment

- Membranes of Reverse Osmosis need cleaning or replacement periodically, in approximately 3 years.

- Steam boilers operating with large loads may not result in optimal output from the Reverse Osmosis unit, hence affecting the quality.

- Water pre-treatment may be required, depending on the reverse osmosis boiler water quality. Highly chlorinated or waters with high scale-forming salts require pre-softening or treatment with sulfite or acid.

- Over 20-25% of Reverse Osmosis water is wasted in the drain if it cannot be used for another purpose.

Challenges Without Reverse Osmosis in Steam Boilers:

Regular maintenance of steam boilers can help to reduce operational costs by keeping low power consumption and avoiding downtime because of repairs. Reverse osmosis in steam boilers as pre-treatment significantly reduces costs due to poor maintenance of the steam boiler.

Reverse osmosis reduces the dissolved solids that result in scaling. Elimination of these contaminates enhances the steam boiler efficiency and increases its productivity. The pH level of boiler water is an essential factor for steam boiler efficiency.

Reverse Osmosis as Solution:

Placing reverse osmosis in the steam boiler before a demineralizer reduces the number of regeneration cycles that reduce the consumption of acid and caustic.

Installing a Reverse Osmosis instead of a softener will reduce fuel costs due to higher operating cycles. It also reduces the steam purity issues due to the low quality of boiler water from the softener that increases the alkalinity in the boiler water, consequently increasing condensate corrosion levels.

Conclusion:

For efficient and reliable steam boilers and thermal solutions for your process plant, contact Rakhoh Boilers, one of the leading boiler manufacturers in Pune with 38+ years of expertise. We have successfully installed 3000+ boilers in over 26 countries worldwide.

For more details on our products and services, visit www.rakhoh.com

- Published in Boiler