One of the major concerns faced by process plant managers is to maintain the functioning of the steam boilers by ensuring its wear and tear to prevent boiler failure, breakdown, or worse, explosion. Process plants generally face challenges such as corrosion, scaling, and foaming in boilers, caused by the poor quality of feed water. Feed water quality is a crucial factor to ensure boiler safety and quality of processing, and therefore, it is necessary to monitor the quality of feed water and treat any impurities before utilizing it in the steam boiler.

Why is Feed Water Important?

Water is one of the excellent raw elements for the heating and power generation process. That is because it extracts more heat when the temperature increases that eventually leads to steam generation. However, water contains some amount of impurities such as dissolved solids and gaseous substances that might prove harmful for the boiler operation.

Feed water quality actually depends on the amount, nature of impurities contained in it, and the capability of the steam boiler to handle it. For instance, low-pressure fire-tube boilers can tolerate feed water hardness if it is treated beforehand.

Types of Impurities that Affects the Boiler Operation:

Here are the different types of impurities found in water that may damage the steam boilers depending on their amount:

Total Alkalinity:

Total alkalinity includes bicarbonate and a slight amount of carbonate in water. Raw water with total alkalinity, if used in the boiler may cause scaling.

Bicarbonate and Carbonate:

As mentioned, total alkalinity contains bicarbonate. If heated, it decomposes to carbonate and carbon dioxide that, on further heating produces caustic (OH) that may or may not be beneficial for the boiler based on its operation. However, carbon dioxide may cause corrosion in boilers.

Calcium:

Calcium is the primary source of hardness in feed water. Calcium salts lead to corrosion in the steam boiler system.

Iron:

Iron is found in a soluble ferrous form that forms insoluble hydroxides or oxides if contacted with air. The iron amount must be reduced if it exceeds 0.3 ppm.

Magnesium:

Magnesium produces hydroxides or silicates in the feed water that forms sludge in the boilers. Magnesium phosphate is a sticky substance that forms scaling.

Chloride:

The concentration of chloride must be avoided in the feed water, as it causes crevice corrosion and pitting in the boiler system.

Silica:

Controlling the amount of silica in feed water is essential, particularly in high-pressure boilers, as it causes scaling problems.

Sulfate:

Sulfate is unavoidable in the feed water, but excessive sulfate may cause corrosion and scaling due to calcium sulfate.

pH:

The pH of the feed water must range between 5.5 and 8.0. If it exceeds the limit, it causes scale formation, and if it reduces the limit, it causes corrosion.

Total Dissolved Solids (TDS):

Total Dissolved Solids must be controlled, as it is the major cause of corrosion in the boiler system. TDS levels must be regularly monitored and maintained.

Hardness:

Hardness in feed water can be determined by the amount of calcium carbonate in water. Excess hardness in feed water may cause deposits and scaling.

Effects of Poor Feed Water Quality in Boilers:

Some of the major problems caused due to the poor quality of the feed water are as follows:

Foaming and Carry Over:

Foaming and carry-over are the most occured problems in steam boilers that are caused due to high levels of solid concentration in feed water.

Corrosion:

Corrosion causes harm to boilers by an electrochemical reaction or by pitting dissolved oxygen in boiler water. In other words, feed water containing high levels of oxygen or carbon dioxide may react with the metal of the boiler and result in corrosion. It causes reduced efficiency, high maintenance costs, pitting, rusting of ferrous metal, and shorter life cycle of boilers.

Treatment for Improving Feed Water Quality:

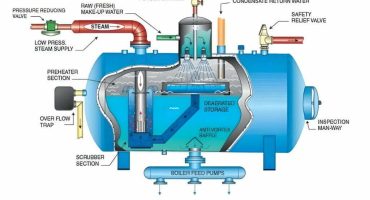

Water is pivotal for steam generation in boilers. Therefore, treating the feed water quality results in safe process operation, increased boiler efficiency, and a long boiler life cycle. Boiler feed water needs treatment to prevent corrosion and scaling in the steam boiler system. Some of the commonly adopted feed water treatment systems are:

- Filtration and Ultra-filtration

- Softening of Ion Exchange

- Coagulation and Chemical Precipitation

- Reverse Osmosis

- Degasification

- Dealkalization

Rakhoh Boilers, with their 38+ years of expertise and experience in boiler manufacturing and thermal solutions, have noted that feed water quality is one of the imperative factors to consider for ensuring safe and reliable boiler operation. Overlooking and neglecting plant maintenance might be hazardous. Rakhoh provides the best boiler-related services for upgrading the process plant operations and productivity.