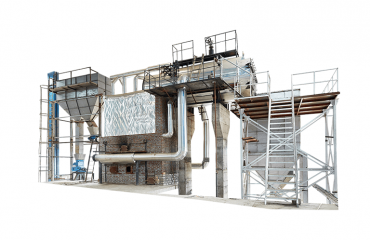

Steam boilers are pivotal for generating pressurized steam in the process and manufacturing sector. Steam has various essential properties that make it suitable and economically beneficial for process operations. It is important to perform an appropriate water treatment program as it affects the overall operating costs of steam boilers, particularly for fuel. The steam is generated in the steam boiler by heating water and later transported through pipes for heating, drying, sterilizing, and power generation purposes. However, as the water converts to steam, it leaves behind dissolved solids that concentrate in the boiler water and needs to be removed by blowdown to keep concentrations within the acceptable limits. Therefore, operating the steam boiler system without condensate treatment may lead to hazardous accidents down the line.

What is Condensate?

The steam exits the boiler through piping to transfer heat to a heat exchanger or steam jacket. When the steam condenses in the pipe, it is called condensate, which consists of minimal impurities in it. Therefore, it is essential to capture and return as much condensate water to the boiler as possible as it saves water, but more importantly, it saves fuel. Freshwater needs to be introduced if condensate is not returned to the steam boiler. The water needs to be preheated that burns fuel. Returning most of the condensate results in saving considerable money in energy.

After cooling of steam, it reverts to a liquid known as condensate. Steam traps collect the condensate for return to the deaerator or feedwater tank efficiently. The condensate blends with the fresh makeup water in a deaerator or feedwater tank and converts to feedwater. It is pumped back into the steam boiler when required to cover the water losses that occurred during steam generation and blowdown. The pressure range of the boiler and the use of the steam determine makeup water quality, ranging from raw water, softened water, to high purity de-mineralized water.

On the other hand, there are certain disadvantages with condensate returns. As the condensate is almost entirely pure water, it is one of the most corrosive elements when introduced to steel and starts to cool. Carbon dioxide (CO2) easily dissolves in water once it cools, and at the precise pH, it starts forming carbonic acid, destroying the steel. It is paramount to maintain the pH within acceptable ranges in the pipes. It is necessary to use a dealkalizer for removal of alkalinity from boiler makeup water or a water softener for removal of hardness from boiler water.

Solution for Condensate Water Treatment:

By following a few basic precautionary methods, condensate can be monitored and handled effectively. Here are the primary steps to ensure the condensate return in a steam boiler,

- The system should be checked for leaks and failed steam traps.

- The pipes and condensate receivers should be insulated properly.

- The steam should be treated chemically with a condensate treatment.

Among the various types of condensate treatments, amines are commonly used. Amines can be classified into two types i.e., filming and volatile. The volatile amines are entirely soluble and can be fed directly in the steam boiler. It is considered volatile as they flash off and carry the steam into the boiler system. Therefore, it is referred to as short-range, medium-range, and long-range neutralizing amines, depending on the distance it can travel “downpipe.” Neutralizing amines are alkaline that neutralize the acids forming in the condensate by raising the pH. It controls corrosion in condensate by eliminating the effects of carbon dioxide and other acid-forming compounds. Neutralizing amines are used for water treatment in a steam boiler to control condensate return line corrosion. The amines do not have any severe impact on copper or copper alloys under normal conditions, that includes pH between 7.5 to 9.0 and a few ppm of amine continuously added to the boiler water.

On the other hand, filming amines are not entirely soluble, and cannot be fed directly into the steam boiler. For effective results of filming amine, it must be introduced directly into the steam header with specially designed injection quills and pumps used for properly dispersing the filming amine throughout the steam. As the steam condenses, filming amine does not dissolve and instead coats the internal surfaces of the pipe with a microscopic layer of chemicals. The material deposits on the internal of the pipe restrict the liquid from entering it. Consequently, it prevents the condensate from coming in contact with the metal and protects the pipe from acid and oxygen pitting.

It is necessary to examine the amine fed in a steam boiler by,

- The chemical feed pump should only activate during the running of the feedwater pump.

- Slug-feed or minimizing daily feed duration leads to temporary high amine concentrations, impacting copper.

- Treatment chemicals should be introduced directly into the steam boiler with the availability of a separate chemical feed line. It can also be added to the feedwater tank or storage tank of the deaerator.

- Amines should not be fed before a deaerator as it may cause loss of the amine.

Conclusion:

Regular maintenance is necessary to ensure the hassle-free operation of the steam boiler. Excess blowdown, scaling, and condensate loss reduce boiler efficiency. Water treatment is crucial for the preventative maintenance program for any steam boiler system. Rakhoh Boilers is a trusted name for over 38+ years for manufacturing steam boilers and boiler accessories of world-class quality. We also provide excellent boiler services like fuel conversion, energy audit, boiler automation, annual boiler maintenance, and steam trap assessment.

For more details on our products and services, visit www.rakhoh.com