Edible Oil is indispensable for cooking purposes all over the world, especially in Indian kitchens. Oilseed production in India is not extensive, and it imports a significant amount of oil from other countries. Some of the Indian states that contribute towards oilseed production are Madhya Pradesh (27%), Rajasthan (20%), Maharashtra (16%), and Gujarat (15%) and account for 80% of total oilseed production in India. Palm oil is the most consumed oil in India, followed by soybean oil that sums up to 65% to 75% of total consumption. The process operation in edible oil refineries includes extraction of oil from oilseeds through an oil mill or chemical extraction by solvent. The oil extracted is later purified, refined, and if required, chemically altered.

The utilization of Oilseeds is classified into two groups:

1. Crushing Oilseeds into Vegetable Oil

2. Edible Oil processing is further classified into two categories:

- Food Processing: It is used as an ingredient in many food items, sauces, and spreads

- Confectionery: It is used as toppings to bakery products and confectionery for improved taste and appearance

Process Stages in Edible Oil Refinery:

Edible oil processing is crucial that requires precision and high-quality standards to ensure its suitability for consumption. Negligence in processing operations may lead to mishaps in the refineries or health issues with the consumer. It would result in the tarnishing of the company’s reputation. Therefore, edible oil refineries follow the standard process that involves ensuring the oil is flavorless, odorless, changes in color and crystal, and molecular structure rearrangement. The edible oil process is categorized into five stages. Let us have a look at it in detail.

Degumming:

Degumming is the first stage in processing oil that involves removing impurities such as phosphatides, also known as gums. The edible oil extracted from sunflower seed, rapeseeds, and soybean consists of phosphatides that need to be removed during the initial stage of oil refining. Due to its emulsifying properties, the degumming stage is essential to prevent the decomposing or darkening of the oil.

Neutralization:

The neutralization process, also known as alkali refining, involves the removal of fatty acids by using an alkali such as caustic soda. As the caustic soda comes in contact with fatty acids, it forms soap stocks that get settled at the bottom of the tank which, is later removed.

Bleaching:

The bleaching process is essential for color removal from the oil. The process destroys contaminants that may have a negative impact on the performance of triacylglycerol present in the edible oil. The bleaching process mixes edible oil with clay absorbent that removes color and decreases the content of residual soap, oxidation properties, gums, chlorophyll, and trace metals. The mixing of absorbents is followed by filtration and a chemical reaction that takes place in bleaching. The bleaching process depends on multiple factors such as temperature, vacuum, moisture, and contact time.

Deodorization:

The Deodorization stage involves processing oil through high-temperature and high-vacuum steam to dispense the oil from odorous and volatile components. The deodorization process is vital for removing flavors and any remaining fatty acids from the oil.

Winterization:

The final stage in edible oil processing is winterization, also known as the dewaxing of edible oil. It is a thermo-mechanical process that includes the crystallization of solid particles in edible oil under determined climatic conditions followed by mechanical separation of the crystals. The edible oil in this process is mixed with a crystallization agent and later processed through a static mixer. For crystallization to take place, the mixture is cooled in an exchanger and then filtered. The winterization process is performed for cotton and sunflower seed oil.

Role of Steam Boilers in Edible Oil Refineries:

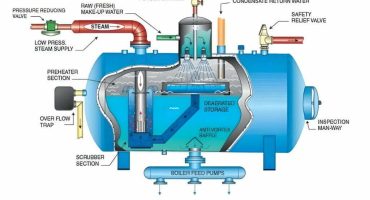

Boilers in edible oil refineries are crucial for many process operations, especially deodorization, to ensure complete removal of components such as color, odor, and moisture that would influence the appearance, smell, and taste of the final product. Edible oil is extracted from crude by the process of deodorization through steam distillation.

Steam boilers in edible oil refineries enable the steam vacuum distillation with high-pressure steam for heating the oil to a determined temperature for removing the impurities and cooling it to regain the characteristics of the oil. Economizer helps boilers in oil refineries by extracting heat from the process to save energy.

Rakhoh Boilers have been manufacturing highly efficient and reliable steam boilers for more than 20 process industries in over 26 countries worldwide. With our extensive knowledge of thermal solutions, we are one of the trusted names as boiler manufacturers. We offer a wide range of solid fuel boilers, oil and gas fired boilers, waste heat recovery boilers, and thermic fluid heaters as per the client’s demand and requirements.

Know more about our products and services on www.rakhoh.com