One of the major concerns of process plant managers and engineers is waste treatment and greenhouse emission control. Industrial wastes, as we know, are one of the major contributors to the increasing pollution in the climate. The wastes released from industrial processes are harmful to both the environment and the people living nearby. It has become prudent for industries to utilize pollution control equipment to aid them in monitoring and properly disposing of the harmful waste release. Wet scrubbers are one of the most efficient pollution control devices used in manufacturing plants among various boiler accessories.

In industrial processes, the combustion of fuel takes place on a large scale. These fuels mainly consist of Carbon (C), Hydrogen (H), Sulfur (S), Nitrogen (N), and Oxygen (O), along with other components. During combustion, fuel, and air ignite and produce flue gases that include Carbon Dioxide (CO2), Sulfur Dioxide (SO2), Water (H2O), and Ash particulates. Among these, Sulfur Dioxide or SO2 and Ash are the most released pollutants in the environment.

What are Wet Scrubbers?

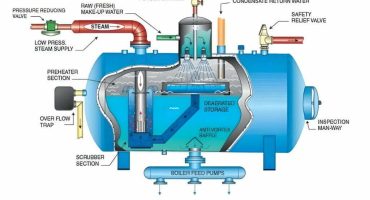

Wet scrubbers are a type of pollution control equipment located in the flue gas path that absorbs Sulfur compounds and oxides from Ash waste and Sulfur Dioxide (SO2). As the name suggests, wet scrubbers involve scrubbing the gases with water for dispensing the dirty pollutants or gases that may lead to harmful emissions and pollution. Wet scrubbers have high efficiency of up to 99.99% in disposing of fine dust particulates from the flue gases in boilers.

Types of Scrubbers:

Scrubbers are classified into two types viz. Dry Scrubbers and Wet Scrubbers. Dry scrubbers are not that widely used compared to wet scrubbers as they do not deliver the same dust removal efficiency as wet scrubbers. Dry Scrubbers perform the procedure of dry reaction, termed as ‘sorbent’ in which components like alkaline slurry are utilized in removing the acid from the flue gases by passing it through the sorbent.

Whereas in wet scrubbers, flue gas is passed through it and administered with a liquid (mostly water) that removes the dust pollutants from gases. Wet scrubbers are preferred by many industries as it is efficient and cost-effective pollution control equipment that removes around 99% of air pollutants from the flue gases.

Working of Wet Scrubbers:

Wet scrubbers function with a parallel flow or counter flow contact of flue gases containing Sulphur Dioxide (SO2) and Ash particulates with water which is diluted with Calcium Carbonate (CaCO3). The sulfur dioxide produces acid in the water, while the calcium carbonate creates alkalinity that destroys the acidic properties of sulfur dioxide.

Water is an ideal choice for the removal of pollutants from flue gases. In wet scrubbers, water is enclosed in a metal container through which the polluted gas is passed. These gases are cleaned and disposed of contaminates with water, and the clean gas is released from the scrubber. Apart from water, there are other liquids as well that effectively removes the pollutants from flue gases. The caustic solution that includes NaOH and Sodium Hydroxide is the preferred liquid for controlling acidic gas. Sodium Carbonate (Na2CO3) and Calcium Hydroxide are also widely used liquids in wet scrubbers.

Wet scrubbers capture the waste particles in their droplets that extracts the pollutants from the gases. The droplets from the released gas are separated with a mist eliminator. The liquid solution used must be properly treated before discharging it in the climate. Wet scrubbers are the only pollution control equipment that can separate both the gas and particulates from a gas stream.

Application of Wet Scrubbers with Different Pollutants:

Wet scrubbers are efficient pollution control equipment that aids in the removal of various pollutants such as:

Volatile Organic Components:

Wet scrubbers are utilized for the removal of volatile organic compounds. The removal efficiency varies depending on the components. However, the average efficiency range is between 70% and 99% and an average of 90% efficiency in most cases.

Vapors and Gases:

Inorganic fumes and gases are the primary contaminants that are removed with wet scrubbers. Pollutants such as hydrogen sulfide, fluorides, chromic acid, chlorides, ammonia, and SO2 mostly achieves removal efficiency ranged between 95% and 99%

Hazardous Pollutants and Particulate Matters:

The efficiency of hazardous dust particles and pollutants is relatively low, ranging between 50% and 95% and depending on the nature and components of the particulates.

-

Advantages of Wet Scrubbers:

- Less Space Requirement

- Low Capital Costs

- Ideal for Optimizing Boiler Operation

- Reduced Fuel Consumption

- Recycle and Reuse of WasteWater

- Manages High-temperature and High-humidity gas streams

- High Efficiency and Easy to Operate

- Collects both Gases and Particulate Matter

- Reduction in Pollution and Greenhouse Emission

-

Industries Using Wet Scrubbers:

- Iron

- Steel

- Stainless Steel

- Zinc

- Copper

- Food

- Dairy

- Distillery

- Cement

- Pharmaceutical

- Paper and Packaging

- Chemicals

- Refinery and Petrochemicals

- Plywood

- Textile

- Power Generation

Wet scrubbers are preferred by many different industries, some of them including:

Rakhoh Boilers has always worked towards the advancement and sustainability of industries and provides highly efficient and customized wet scrubbers that are ideal for handling high gas volumes and high-pressure drops and capable of collecting fine dust particulates. It is easy to install and ensures uniform distribution of water and avoids the possibility of scaling.